Removal processes

PECM - Precision Electro Chemical Machining by Ter Hoek Vonkerosie

Contactless and precisely metal parts are machined using the PECM process.

Contactless and precisely metal parts are machined using the PECM process.

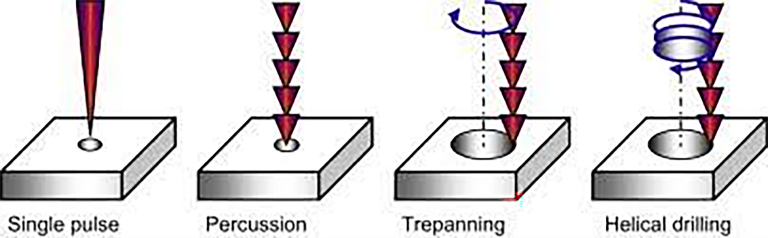

Micro machining, like drilling holes in metal parts with a very small diameter (down to tens of microns) without burrs.

Read more See poster

GF Mikron MILL S/X U machines are able to combine Milling and jig grinding on the same machine.

Grinding is a type of abrasive machining process which uses a grinding wheel as cutting tool.

In the PECM process, an electric current is passed through an electrolyte between a workpiece and an electrode, which selectively removes the workpiece. This is done without mechanical contact. This enables highly complex and delicate workpieces to be produced with exceptional precision.

Read more See poster

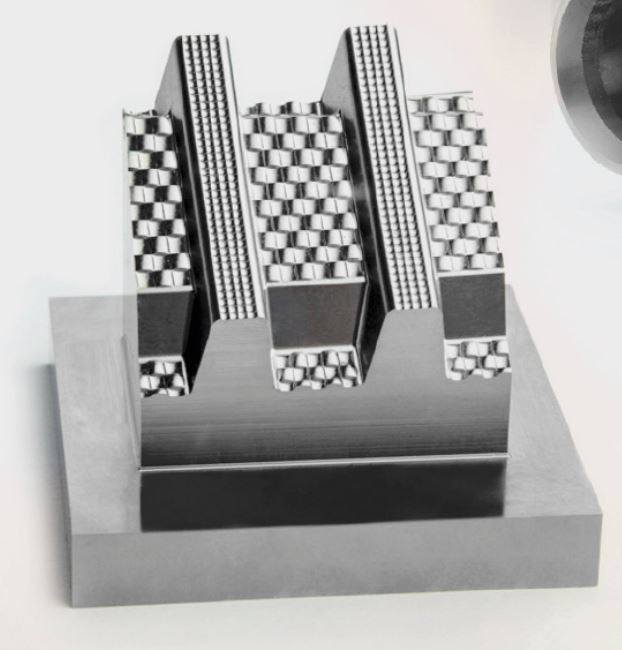

Laser 3D Surface Processing is a fully digital solution that allows to ablate material on the surface of almost any kind of part and material. It is a technology of choice for texturing, structuring, thin film ablation, as well as decoration and coloring, marking, engraving.

The aim of this Manufacturing Technology Conference is to bring together technicians from the design and manufacturing industry to share knowledge about manufacturability. With this annual Manufacturing Technology Conference, we increase knowledge about manufacturability for developers and help them look for possibilities that were previously unknown.

Sign up as a visitor Sign up as a participant